The EES Is a spray system for the concentration of aqueous solutions and recovery of minerals

The EES system, comprises of a unique elevated low pressure spraying system which provides a large evaporation surface area by means of uniform size falling droplets.

The modular system solves the size problem of conventional evaporation ponds by requiring land surface area, which is six to ten times smaller than that needed for conventional evaporation ponds.

TYPICAL APPLICATIONS

Evaporation of industrial effluents (chemical, petrochemical, textiles, foods).

Evaporation of cooling tower blow down in a power industry.

Evaporation of concentrated brines (25%) for the production of valuable minerals.

Evaporation of sea water to produce concentrated brine solution for enhancing salt production or other uses.

Evaporation of agricultural drainage for water salinity and level control.

Evaporation of lake water over drying ponds for keeping lake salinity at a low level.

The system utilizes enthalpy from ambient air to evaporate water from liquid droplets.

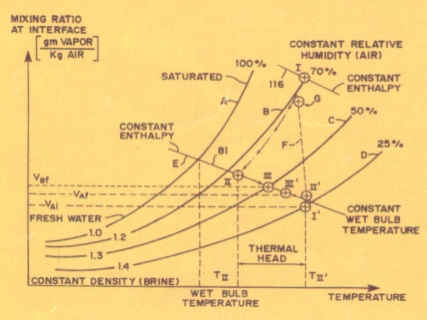

Contrary to conventional cooling towers or spray ponds, the mass flow of air in the EES system is much larger than the mass flow of water, resulting in rapid cooling of the liquid to the wet bulb temperature of the air (from point I to point II in the psychrometric diagram-Fig. A).

During this cooling, the change in air parameters is almost negligible (from I to II', in the same diagram). At this stage evaporation is less than 1 %.

Subsequently the liquid droplets warm to a temperature shown as point III on the diagram while the air cools to a temperature represented by point III'.

This part of the process is accompanied by evaporation due to the large amount of heat which is transferred at constant enthalpy from the air to the liquid.

Specially selected nozzles which produce a shower of droplets with desired diameter and having a very narrow size distribution, ensure a high evaporation rate and low carry over.

Only a minimal number of large droplets, which may be carried away by the wind, are present in the shower.

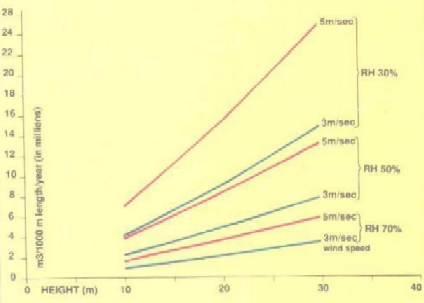

The rate of evaporation depends on droplet size, the height of the spraying system above the ground and the atmospheric conditions, i.e., air relative humidity (R.H.) and wind speed (Fig B).

Figure A

Figure B